Project Canopy

Montréal, 2024

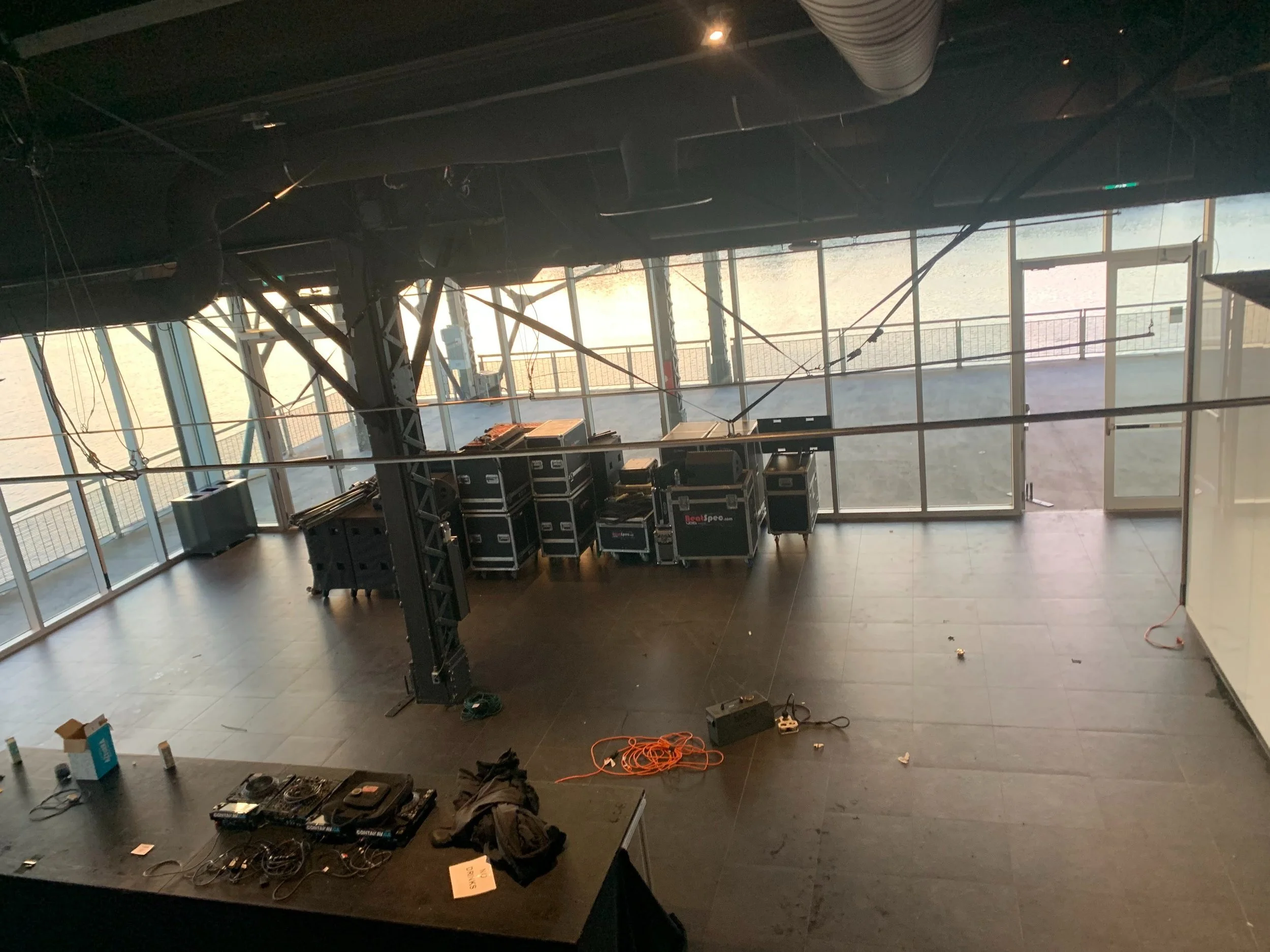

Project Canopy is an evolution of project XOXO and consists of a set of 24 LED commissioned by Exposé Noir, a techno collective based in Montréal, Canada. The structure was part of Exposé Noir's 3-day long festival held at Montreal’s Science Center between May 17th and May 19th 2024. The event drew over 2,500 attendees and showcased a lineup of international talent. Highlights included Berghain doorman and photographer Sven Marquardt, alongside DJs Massimiliano Pagliara, Budino, DDan, Mary Davidson, and Regular Fantasy.

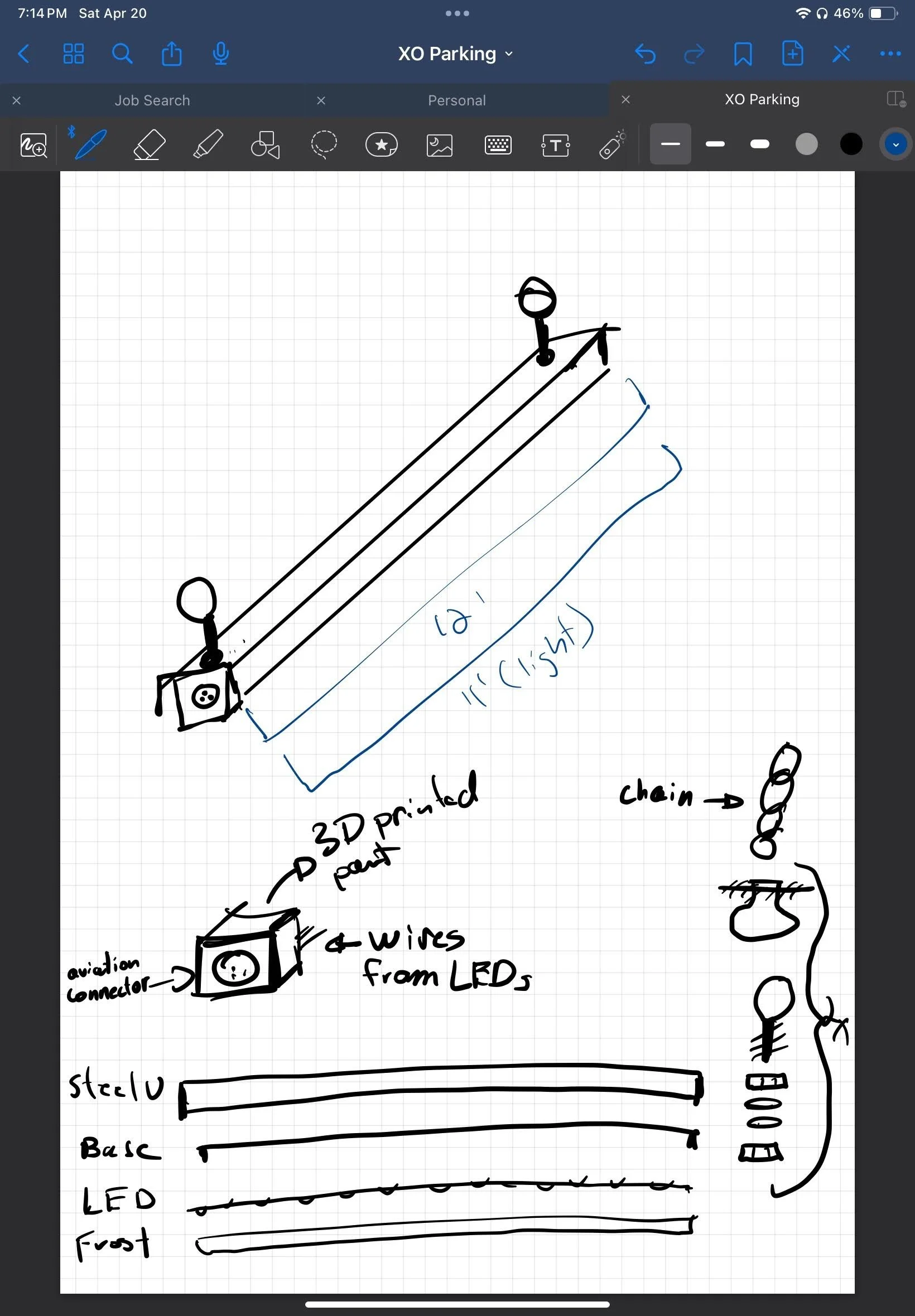

Each LED fixture is 12 feet in length and is controlled through a DMX interface. I was responsible for system conceptualization, component selection, manufacturing, and overseeing the on-site installation team.

Like XOXO, the system is fully modular, and each of the 16 fixtures consists of 3 parts: an LED component, a DMX interface, and a custom cable to connect the two.

Fixtures are connected in a daisy chain via DMX cables to the DMX interface, which controls the light show.

The original plan was to 3D print a bracket for the connections. However, I used off-the-shelf hardware to secure the wires on each light. This solution was a better fit for the needs of the project.

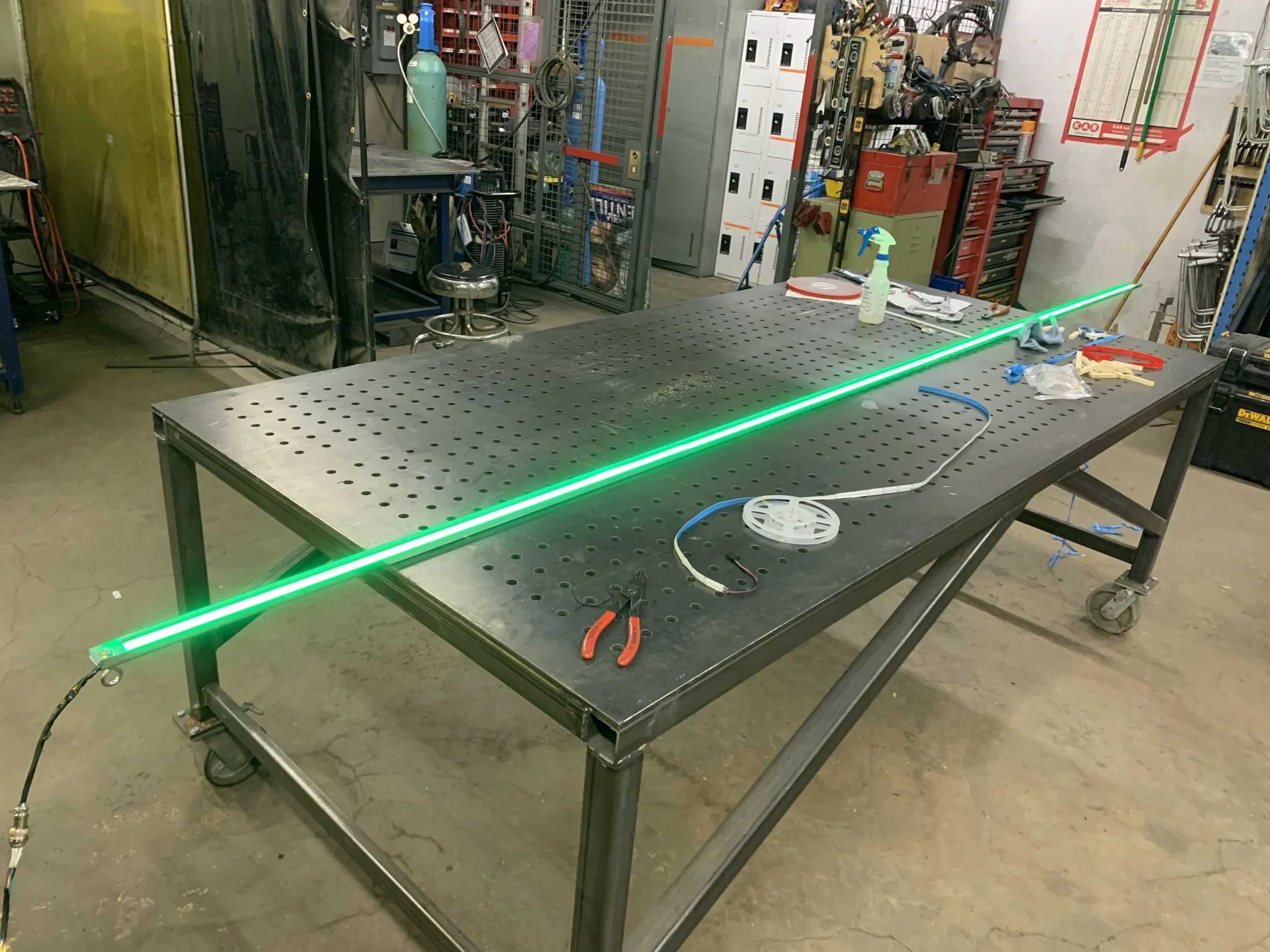

We used 12’ steel U-channels as the base for each fixture. This medium was well-suited for our project as it offered rigidity, yet could easily be pierced and glued to other materials. I built the suspension mechanism with off-the-shelf hardware from Home Depot (i.e. hook bolts and nuts).

I built the fixtures in the metal shop of l’EspaceMaker in Montreal. I designed a simple cardboard guide to easily align the holes on the drill press and ensure regularity between units.

The light source of each fixture was a 5m-long RGB LED strip. While somewhat costly, this option offered good brightness and reliability. It also features a baked-in diffuser. I chose to use RGB instead of addressable LEDs to simplify the system. The setup counted 40 lights (16 from XOXO and 24 from Canopy), each of which used 3 DMX channels, totaling 120 channels. Addressable LEDs would have catapulted the number of channels one or two orders of magnitudes North of that figure. Nonetheless, I would love to experiment with this in the future.

Manufacturing the fixtures ended up being quite a challenge. Building 24 units over a week required patience and greater attention to manufacturing processes. I tested different methods to find the ones that would scale the best.

One of the biggest challenges was to glue the aluminum LED rail to the steel U-channels. After testing different glues and epoxies, I found that the best option was heavy-duty double-sided tape. A friend suggested using UHB tape - a knock-off of the expensive 3M version.

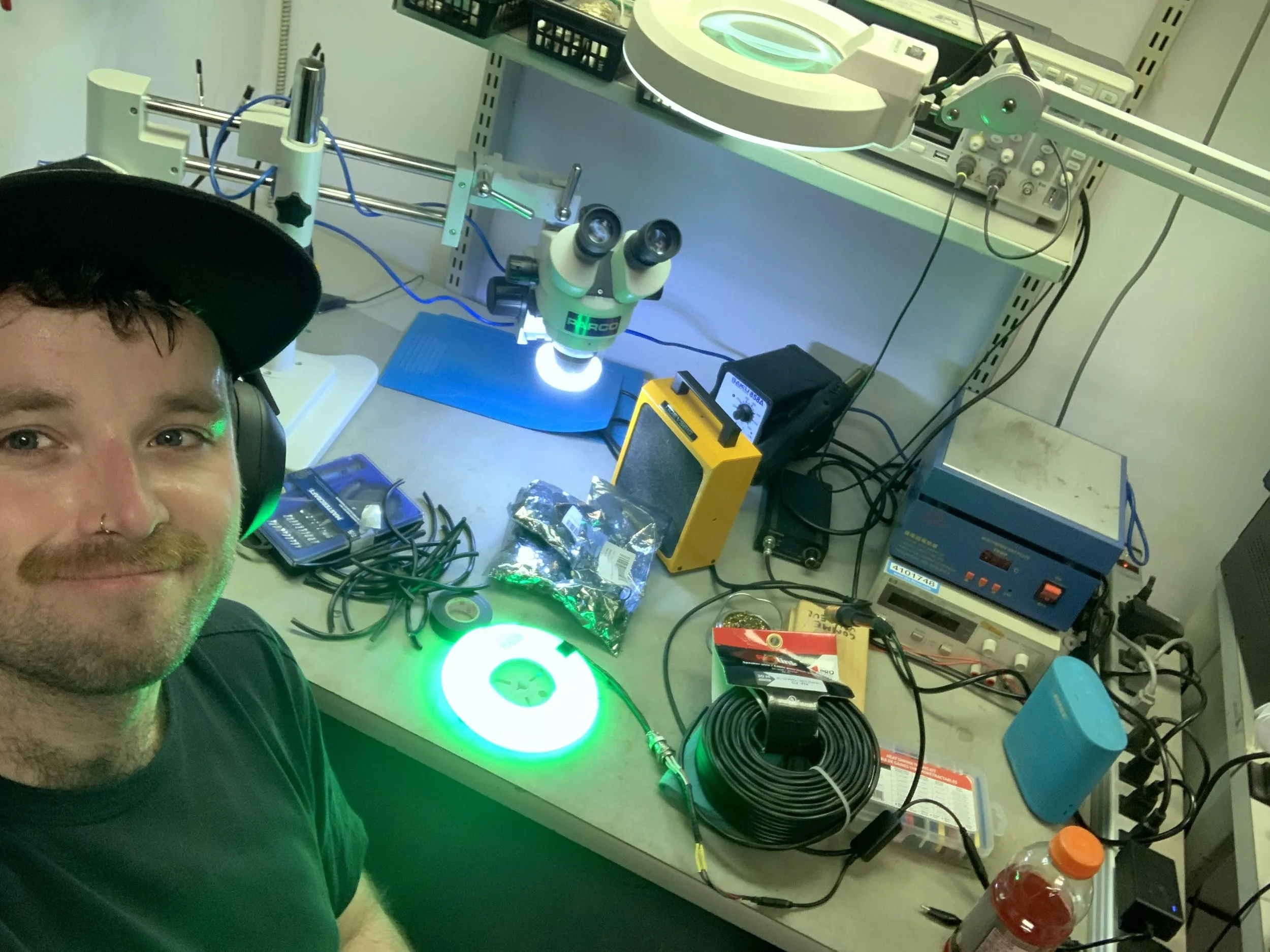

I also tested different soldering processes to simplify the assembly. Unsurprisingly, batching each manufacturing step ended up being the fastest method. I would thus complete each step 24 times before moving to the next assembly step.

Finally, I found it useful to build testing tools specifically for the project. For instance, I built a non-DMX control unit to test every LED assembly without needing a DMX control unit.

Installing the lights was more complex than I anticipated. I led. a team of 8 people during the installation. I had designed a metal wire system to hang them with clamps from ceiling H-beams. To do so, I used steel wire and aluminum crimps. However, I hadn't realized that the ceiling was slanted. There was around a 1.5’ ceiling height difference between both ends of the room. My team and I had to rebuild the cables on the fly using new crimps, zip ties, and ingenuity. We looped the cables and shortened them to make sure that everything was totally flat.

The second challenge stemmed from how I had overestimated the rigidity of the steel U-channels. They hung from both ends, leaving little support in the middle. This made them sag, creating an arc instead of a straight line. To solve this issue, I designed a new system utilizing a ratchet linking the middle of each fixture to both of their anchors. This system worked quite well as it allowed to modulated the upward lift on each fixture by tightening the strap.